The NOCSAE headform

Football Helmet Testing

NOCSAE developed and pioneered the first and only biofidelic headform

Overview

The NOCSAE headform is one of the pieces of equipment specified in our standards for headgear and helmet testing. As the helmet (with a headform inside) is impacted during testing, the headform mimics the human head’s response to these impacts. Instruments inside the headform gather data, which ultimately is used in a severity index calculation. Use of a biofidelic headform is the most accurate way to measure how well a helmet type protects the head and brain.

The Headform in Testing

NOCSAE testing standards require the headform in the drop test and pneumatic ram test methods. A single, complete test of a helmet type includes both the drop and pneumatic ram methods.

Drop Test

For the drop test method, a headform is attached to a twin-wire impactor machine that allows a headform and helmet to freefall onto a steel anvil. The headform and helmet are dropped from different heights to create different impact speeds. This test method involves 29 impacts (at specific speeds) onto six different impact locations on the helmet, including one random impact location. There are four lower-speed impacts, and four impacts at high temperatures. The helmet must pass each impact event.

Pneumatic Ram Test

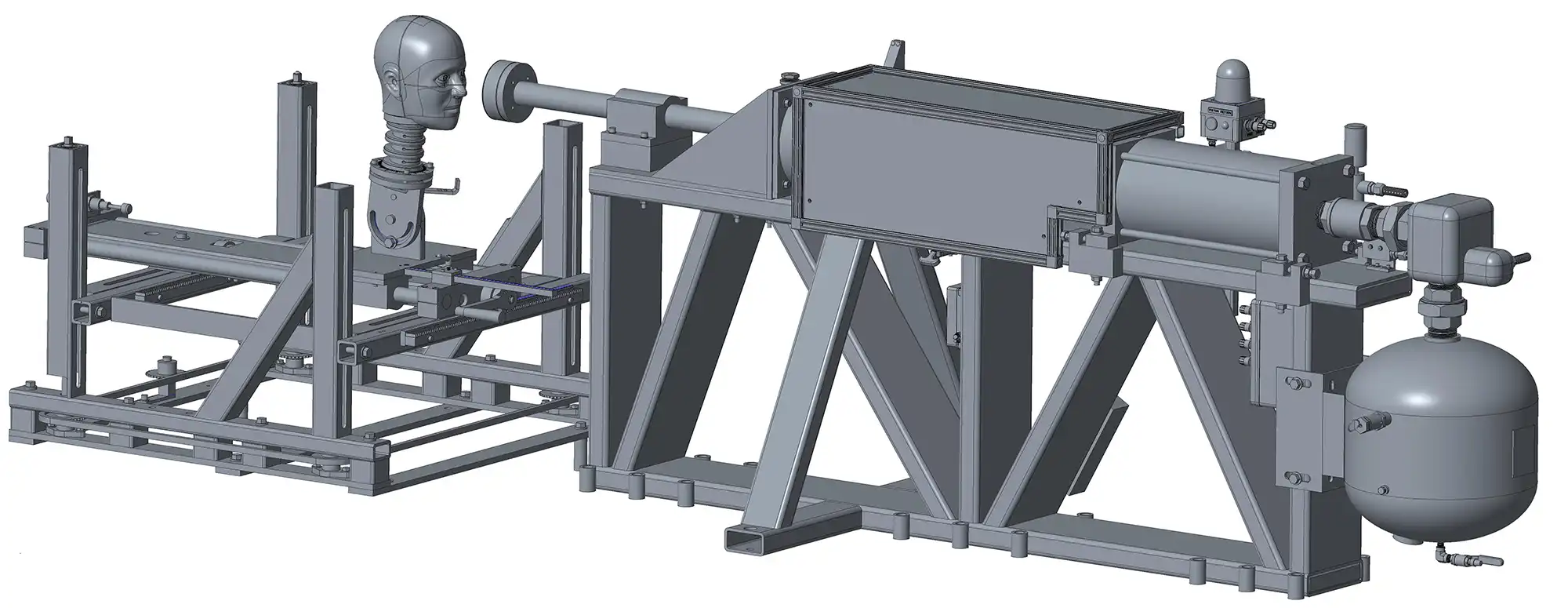

For the pneumatic ram method, the headform is mounted to a linear bearing table, which allows the headform and helmet to move after an impact.

Helmets are struck by a ram on six predetermined locations and one random location. Inside the headform, accelerometers measure accelerations 10,000 times per second in three directions during each test impact. Helmets must meet the standard at all impacts of the pneumatic ram test.

The pneumatic ram can deliver impacts in locations and from directions that are not possible with the drop test system. This test method was developed to collect and measure impacts that result in rotational accelerations, which is a type of force involved in many concussions.

Pneumatic Ram Impactor with NOCSAE Headform